Perforated Exhaust Pipe Manufacturer & Supplier in India - Bhansali Wire Mesh

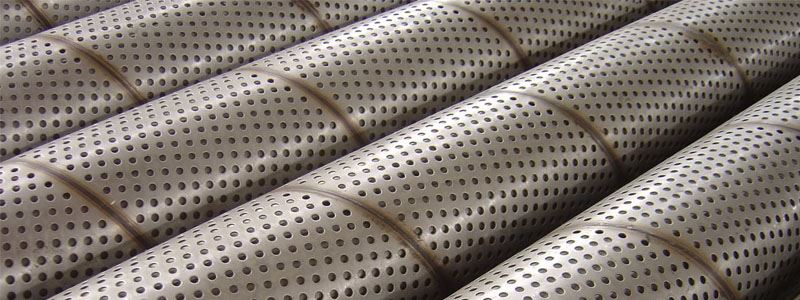

Bhansali Wire Mesh is one of the leading Perforated Exhaust Pipe Manufacturers in India. We offer the best quality product at a reasonable price for our customers to make their work easier and more efficient. A Perforated Exhaust Pipes is a pipe that has been punched with holes along its length. Perforated Exhaust Pipe Manufacturer in India also offer competitive pricing, due to the country’s low labor costs and access to raw materials.

our premium perforated pipe is significant and Worldwide demand. Bhansali Wire Mesh is an established brand. Additionally, a variety of other grades are in stock, including. Perforated Exhaust Pipe Manufacturer in India is highly competitive and dynamic with quality and customer satisfaction.

Perforated Exhaust Pipe Manufacturer, Perforated Exhaust Pipe Supplier, Perforated Exhaust Pipe Stockist, Perforated Exhaust Pipe Exporter in India

We are one of India's largest Perforated Exhaust Pipe Manufacturers, Supplier & Stockist in India. Perforated Exhaust Pipes are available in a wide range of Forms, Sizes and Thicknesses. Perforated Exhaust Pipe Supplier in India ensure that they have a good understanding of customer needs to provide high-quality products that meet the required industry standards. We are also a High-Standard Wire Mesh Supplier.

Top Selling Perforated Exhaust Pipe

We will explore the different types of Perforated Exhaust Pipe and their uses.

Perforated Exhaust Pipe Specification & Grades:

A variety of Perforated Exhaust Pipe specifications are available based on end use and project requirements.

| Specification |

| Finish |

Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| Origin |

European, Japanese, Korean, US, Russian, Indian (Strictly No Chinese Material) |

| Test |

Hardness Test,

Flattening Test,

Pitting Resistance Test,

Chemical Analysis – Spectro Analysis,

Micro and MacroTest,

Flaring Test,

Intergranular Corrosion (IGC) Test,

Mechanical Testing Such as Tensile of Area,

Positive Material Identification – PMI Testing,

|

| Marking |

All Stainless Steel Seamless Pipes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Thickness |

exact 0.25, 0.28, 0.32, 0.37, 0.41, 0.51, 0.61, 0.71, 0.91, 1.11, 1.15, 1.41 mm |

| size |

5.0 mm – 1219.2 mm |

| Outside Diameter |

6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Thickness Range |

0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Type |

Seamless / ERW / Welded / Fabricated / CDW |

| Form |

Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes |

| Length |

Single Random, Double Random & Required Length End: Plain End, Beveled End, Treaded |

| End Protection |

Plastic Caps |

| Surface Finish: |

2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements |

| Delivery Condition |

Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Inspection, Test Reports |

Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing |

Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials |

Sizes and Specifications other than above can be manufactured on request |

| Our Presence |

USA, Canada, Australia, UK, Malaysia, Poland, Iran, Italy, Singapore, UAE |

| Material Test Certificates (MTC) |

Material Test Certificates (MTC) as per EN 10204/ 3.1B and EN 10204 3.2 |

| Seamless Pipe size |

5.0 mm – 1219.2 mm |

| Schedule |

SCH5, SCH10, SCH40, STD, SCH80, SCH160 |

| Pipe End |

Plain End, Beveled End, Treaded. |

| Size |

4 to 219mm W. T.: 0.5 to 20mm |

Perforated Exhaust Pipe Manufacturer Mechanical Properties

The mechanical properties of pipe can vary

depending on the process used by the Perforated Exhaust Pipe Manufacturers, but they generally

have a yield strength of around 47,900 psi.

| Material |

Heat |

Temperure |

Tensile Strength |

Yield Strength |

Elongation %, Min |

| Treatment |

Min. |

Ksi (MPa), Min. |

Ksi (MPa), Min. |

| |

º F(º C) |

|

|

| TP304 |

Solution |

1900 (1040) |

75(515) |

30(205) |

35 |

| TP304L |

Solution |

1900 (1040) |

70(485) |

25(170) |

35 |

| TP316 |

Solution |

1900(1040) |

75(515) |

30(205) |

35 |

| TP316L |

Solution |

1900(1040) |

70(485) |

25(170) |

35 |

Perforated Exhaust Pipe Chemical Composition

According to the Perforated Exhaust Pipe Manufacturers,

the chemical composition of wire mesh can differ depending

on the application, but they generally contain 0.25.

| GRADES |

UNS |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

Ti |

Nb |

N |

| TP304 |

S30400 |

0.08 |

2 |

0.045 |

0.03 |

1 |

18.0-20.0 |

8.0-11.0 |

|

|

|

|

| TP304L |

S30403 |

0.035 |

2 |

0.045 |

0.03 |

1 |

18.0-20.0 |

8.0-13.0 |

|

|

|

|

| TP316 |

S3160 |

0.08 |

2 |

0.045 |

0.03 |

1 |

16.0-18.0 |

11.0-14.0 |

2.0-3.0 |

|

|

|

| TP316L |

S31603 |

0.035 |

2 |

0.045 |

0.03 |

1 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

|

|

|

Perforated Exhaust Pipe Manufacturer Equivalent Grades

According to the Perforated Exhaust Pipe Manufacturers, there are three

main grades of stainless steel employed for pipe:

grade 2 (commercial), grade 5 (aerospace) and grade 7 (nuclear).

The choice of grade depends on the operating conditions and end

use of the equipment. There are numerous grades of stainless

steel available depending on the desired application.

The most typically used grades include:

| GRADE |

UNS NO |

DIN/WERKSTOFF |

| 304 |

S30400 |

1.4301 |

| 304L |

S30403 |

1.4306 |

| 316 |

S31600 |

1.4436 |

| 316L |

S31603 |

1.4404 |

Perforated Exhaust Pipe Manufacturer Weight Chart

The weight of Perforated Exhaust Pipe differs from the

thickness and composition. Perforated Exhaust Pipe Manufacturers usually use a

grade that has good strength and toughness.

| Perforated Exhaust Pipe |

Lbs. Per Square Foot |

|

GAUGE

|

HOLES

|

CENTERS

|

OPEN AREA %

|

|

30

|

.020"

|

.045"

|

20%

|

|

26

|

1/32"

|

1/16"

|

22%

|

|

26

|

.033"

|

.055" STRAIGHT

|

29%

|

|

24

|

3/64"

|

3/32"

|

23%

|

|

26

|

.050"

|

.066" STRAIGHT

|

52%

|

|

26

|

050"

|

5/64"

|

37%

|

|

22

|

1/16"

|

3/32"

|

40%

|

|

22,26

|

1/16"

|

7/64"

|

30%

|

|

20,18

|

1/16"

|

1/8"

|

23%

|

|

22,20

|

5/64

|

1/8"

|

35%

|

|

20,18,16

|

3/32

|

5/32"

|

33%

|

|

22

|

.117

|

5/32"

|

51%

|

|

26-11

|

1/8

|

3/16"

|

40%

|

|

20-16

|

5/32"

|

3/16"

|

63%

|

|

24-14

|

3/16"

|

1/4"

|

51%

|

|

18,11

|

3/16"

|

5/16"

|

33%

|

|

22-16

|

1/4"

|

5/16"

|

58%

|

|

20-14,11

|

1/4"

|

3/8"

|

40%

|

|

10

|

3/8"

|

1/2"

|

51%

|

|

18,16,11

|

3/8"

|

9/16"

|

40%

|

|

20,16,14,11

|

1/2"

|

11/16"

|

48%

|

|

11

|

3/4"

|

1"

|

51%

|

Bhansali Wire Mesh is a leading Perforated Exhaust Pipe Manufacturer, Supplier & Stockist in India.

Small slots or holes are added into perforated pipes so that water can easily enter or exit. Due to its capacity to both absorb and drain water, this type of pipe is commonly utilized for outdoor applications as well as underground drainage systems.

Call +91 96196 12233 or contact info@bhansalisteels.com if you need a specific size, thickness, or coating on products.

Perforated Exhaust Pipe Additional Information

- Payment Modes: LC (Letter of Credit), TT (Telegraphic Transfer or Wire Transfer), Cheque, and others

- Packaging: Perforated Exhaust Pipe is packaged with caution and safety so they reach our client’s as good as they would expect. Packaging Charges Extra.

- Pipe Port of Dispatch: Mumbai or Kalamboli ports in the Maharashtra state of India.

- Pipe Tax: 18% GST

Perforated Exhaust Pipe Applications and Uses

Perforated Exhaust Pipe is used in various industries worldwide. Bhansali Wire Mesh is known internationally for our quality of Perforated Exhaust Pipe that is used in different industries and applications.

- Perforated Exhaust Pipe are used in Chemical / Petrochemical

- Perforated Exhaust Pipe are used in Mechanical and Plant engineering

- Perforated Exhaust Pipe are used in Food, Beverage, and Dairy

- Perforated Exhaust Pipe are used in Oil and Gas

- Perforated Exhaust Pipe are used in Power

- Perforated Exhaust Pipe are used in Process Instrumentation

Client Project Report

Our Perforated Exhaust Pipe is of the highest quality, which is why our large customer adore them. Bhansali Wire Mesh Perforated Exhaust Pipe is used in a variety of projects all around the world. We have regular Perforated Exhaust Pipe demand from clients in six different nations, and we export Perforated Exhaust Pipe to another 50+ countries.

| Products We Supplied

|

Cities |

|

Perforated Exhaust Pipe Supply in Perforated Exhaust Pipe Manufacturing Facilities

|

Saudi Arabia

|

|

Monel Perforated Exhaust Pipe supply

|

Oman

|

|

Steel Perforated Exhaust Pipe

|

Kuwait

|

|

Stainless Steel 304 Perforated Exhaust Pipe Supply

|

Qatar

|

Perforated Exhaust Pipe Exporter

More than 24 tonnes of Perforated Exhaust Pipe are shipped each year, with Bhansali Wire Mesh accounting for 30% of the total. In Germany, United Arab Emirates, Italy, France, United Kingdom, Canada, United States, Australia, Netherlands, Mexico, Saudi Arabia, Iran, and Oman, we have a large client base. Perforated Exhaust Pipe is being exported to more nations regularly, and we're meeting new clientele from all over the world.

| Countries We Export |

| Saudi Arabia |

Oman |

Kuwait |

Netherlands |

Iran |

| Bahrain |

Qatar |

UAE |

Africa |

Brazil |

| Nigeria |

Mexico |

Canada |

Venezuela |

UK |

| United States |

South Africa |

Malaysia |

Bangladesh |

Turkey |

| Singapore |

Sri Lanka |

Australia |

Belgium |

Germany |

| France |

Italy |

South Korea |

Poland |

Egypt |